Facecream filling solution

13 Jul

13 Jul

Creams and lotions are the most important step in basic skin care. The whitening and anti-aging active ingredients in creams and lotions can be better absorbed by the skin, so it is very important to have a good cream/lotion. Skin care steps are: makeup removal, cleansing, exfoliation, massage, gel, mask, lotion, facial essence, eye essence, lotion, eye cream, face cream, barrier cream, sunscreen

The biggest function of the cream is to moisturize and nourish.

With BOTTLINGLIFE special customized cream filling capping machine .we can improve your production

Our Automatic facial cream filling machine is due to the development of the daily chemical products, cosmetics industry for liquid type, cream type products manufacturers pay great attention to the production efficiency requirements, the production of manufacturing out

The cream filling machine is corrosion-resistant and moisture-proof, made of 304/316 material, with a very long service life.

The filling machine is equipped with high-definition intelligent touch screen, with production count, filling volume adjustment, filling speed adjustment, production parameters adjustment and other one-touch start automation, filling the bottle type can be adjusted according to customer requirements, very convenient.

Cream filling machine is the ideal filling machine equipment for cosmetics, daily chemicals, food and other liquid, cream material industry.

Can be customized to produce at all customer functional requirements, cream filling and capping machine, with filling and capping integrated production.

Examples of filling products such as: a variety of liquid, cream type, such as laundry detergent, cream, skin care liquid, shampoo, etc..

- This face cream filling machine equipment adopts cylinder driven filling head filling, which can carry out multi-head filling, fast speed and higher filling accuracy.

- Using touch screen system control: digital display control, filling volume and filling speed can be adjusted at will, one key automatic, easy to operate.

- The material contact parts are made of sanitary stainless steel 314/316L, which meets GMP requirements.

- The filling head adopts anti-drawing and lifting filling device, with self-suction function to prevent oil overflow, and the top of the filling machine has a storage box.

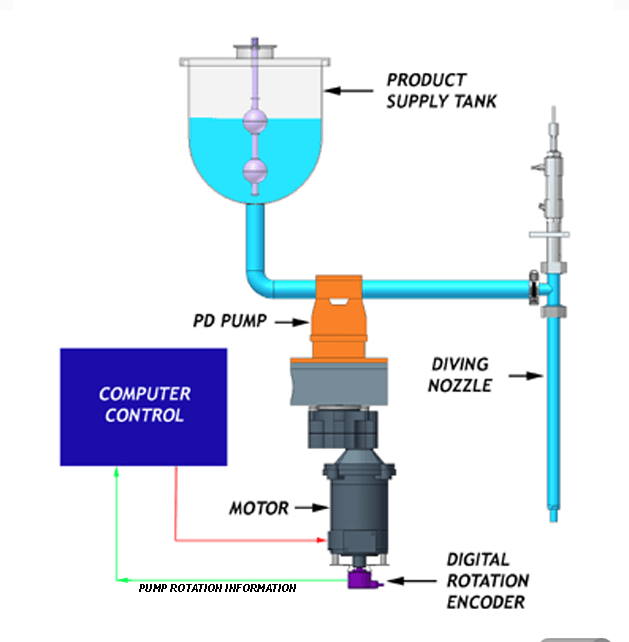

The principle of paste filling machine is to feed the material by piston pump, push the piston through the cylinder and then pump the material into the container cylinder.

A check valve is connected in the middle, and then the cylinder is pushed to remove the material from the cylinder. The material flows back to the filling head through the piston to achieve filling

Related