Round Bottle Adhesive Sticker Labeling Machine

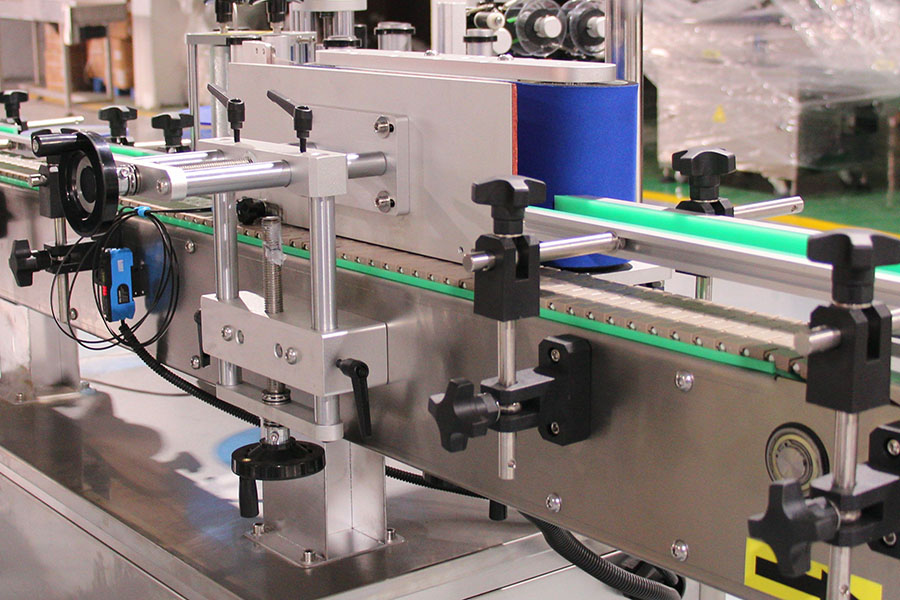

Automatic linear labelling machine for the precise adhesive labelling of round shape bottle

This labelling machine can be easily integrated into a future or existing bottling line.

This linear adhesive labelling machine is suitable for all sectors of activity:

- cosmetics and hygiene (shampoo, shower gel, soap, cream, body oil, etc.),

- food industry (vinegar, oil, sauce, fruit juice, syrup, honey, jam, marmalade, mustard, spices, etc.),

- chemistry (detergent, solvent, household products, motor oil, etc.),

- paint and varnish (pots, drum, etc.).

This labeling machine is designed to apply a partial or full wrap-around label to round bottles. This is done using a motorized wrap-around system that electronically synchronizes the speed of the labeling head with the speed of the container.

This System can be equipped with a choice of labeling heads with different sized wrap-around systems in conjunction with various indexing systems to suit your speed and application requirements. Indexing systems options include a feedscrew, an indexing wheel, and a double belt bottle separator.

Speed Up to of 60 bpm

Adopt mature PLC control system technology; make the whole machine stable and high-speed

Use touch screen control system, make operation simple, practical and efficient

Screw adjust the suppression mechanism, high accuracy

Synchronization chain mechanism, to ensure smooth and precise calibration

Transparent sticker labeling without foam, adhesive sticker labeling without wrinkle

Work for all round shape bottle

Hot stampprinter is for optional

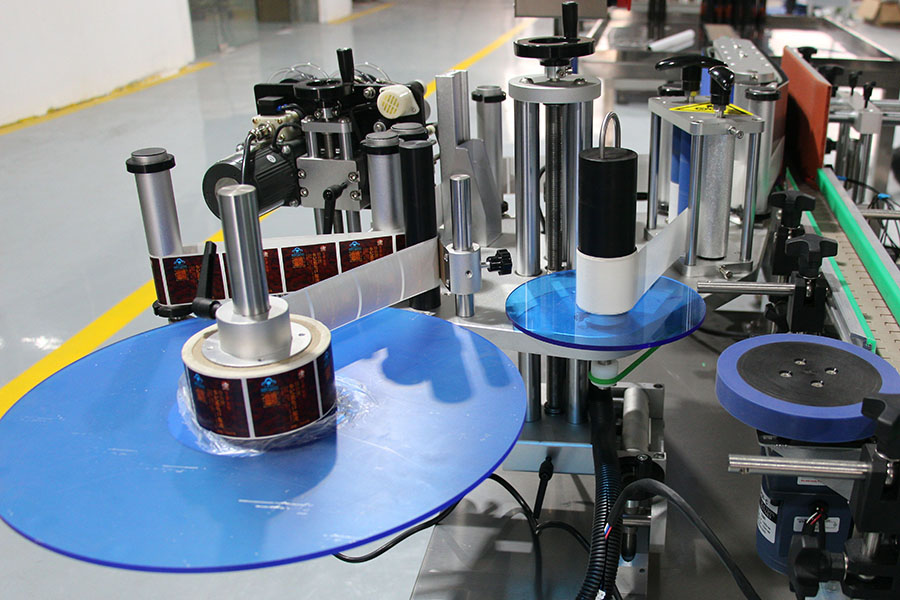

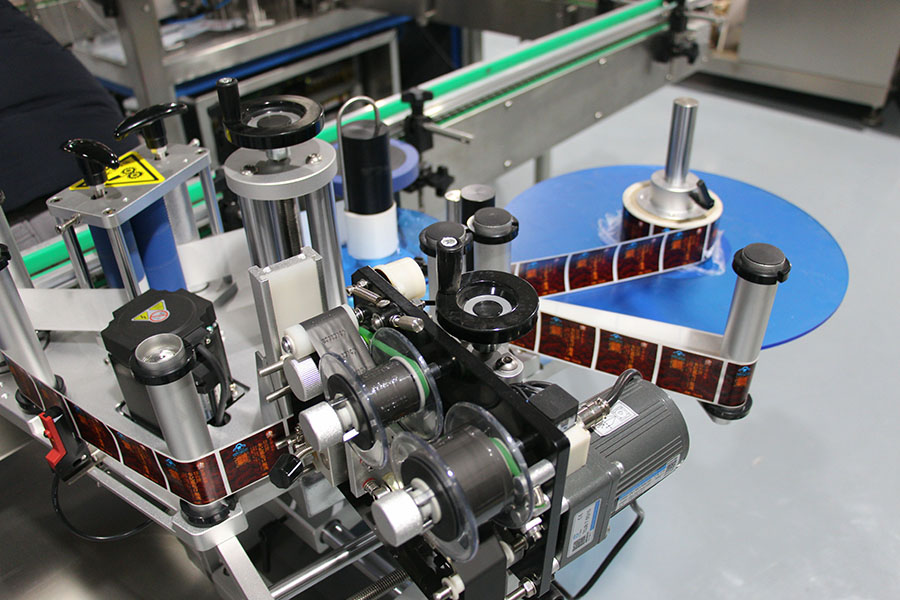

• One electronic labeling head

• Height: minimum and maximum backing paper 20 x

100 mm (Labels 8 x 98 mm)

• Length: minimum and maximum 8 x 250 mm

• Minimum gap between labels 2 mm

• Maximum roll size 380 mm (15’’)

• Core size: from 40 to 75 mm

• Maximum dispensing speed of 40 bottle per

minute

• High precision Stepper motor

• System pull push for label stability

• Bottle detection with photo start programmable directly

from the touch screen control

• Label detection with standard photo stop detection

mounted on a sliding arm

• Height adjustment system of the labeling head with

hand wheel for easy change over

• Change over label with automatic self-learning device

"L” Shape Arm for Vision / Coding System Installation

To integrated a Hot stamp, thermal transfer coder, or vision system onto the

labeling head directly, giving you more space to do the equipment adjustmen

Leuze Eye Sensor

Sensor able to detect every style of label onto backing paper with minimum adjustment

|

Voltage |

220V, 50HZ |

|

Power |

2KW |

|

Air pressure |

0.3Mpa |

|

Labeling Speed |

30-100pcs/min |

|

Labeling Accuracy |

±1mm |

|

Object Size |

30-200 mm(H),30-100 mm(W) |

|

Label Size |

25-300 mm(L),20-180 mm(W) |

|

Roll Size |

76 mm(Inside),380 mm(Outside) |

|

Dimension |

2800(L)×1600(W)×1500(H) mm |

1.Where is it located the manufacturer?

We are located in shanghai china

2.How long is the warranty?

The warranty is one year with easy damage part for free

3.How long it would take to deliver if I decided to purchase?

Because all of our machine will be customized according to your bottles .so the production time is about 30-40 days after get your bottle samples and deposit .?

4.How is the cost of power per day of the machine?

the machine power need about2kw-5kw

5.In case of breakdown the parts are it easily findable and deliver quickly?

Yes.we will provide you one years warranty with any easy damage spare part for free with free shipping .

6.What resources does your company offer in terms of set up and additional support?

Our engineer is avaliable to set up machine and provide technical support for you.beside this .we provide manual book and video support

7.Can i send bottle and cap test ?how much would you need ?can you make a video of this ?

our machine is customized according to the bottle size and cap size .

when machine is ready we will send you test video with your bottle and caps .bottle we need about 100 for each size .cap we need 200 for each size

8.WHAT ABOUT SPARE PARTS?

We will send enough perishable spare parts for one year with the machine shipped together. We will offer spare parts within the warranty term.

9.HOW DO I TEST THE MACHINE BEFORE SHIPMENT?

We will run the machine for 48 hours .and send you the test video .we can also have remote FAT

10.Do you have certificates?

Yes.we have been certified .we can also provide IQ OQ documentation.