Propolis Filling Solution

19 Jul

19 Jul

Propolis Filling Line is an automated production line used to produce propolis products. Propolis is a natural substance made from plant resin collected by bees and mixed with bee secretions and enzymes and other ingredients, which is widely used in health care products and medicine. The main job of a propolis filling line is to fill propolis products into suitable containers and complete processes such as capping and labeling where required.

Advantages of propolis filling line include:

Automated production: the propolis filling line adopts an automated control system, which can significantly improve production efficiency, reduce manual operation and lower labor costs.

Accurate filling: The filling line is equipped with high-precision filling equipment to ensure that each product is filled evenly and accurately, avoiding waste and product quality problems.

Maintaining product quality: The filling line adopts sealed packaging, which can maintain the freshness and quality of propolis products and prolong the shelf life.

Capping machine is the key equipment in the propolis filling line and its main advantages include:

Automatic capping: The capping machine is able to automatically complete the capping operation of the container, avoiding the instability and inconsistency problems that may occur when capping manually.

High efficiency: the capping machine can complete capping quickly and accurately, which greatly improves production efficiency and saves time and labor costs.

Widely applicable: the capping machine can be applied to various specifications and types of containers with high flexibility and a wide range of applications.

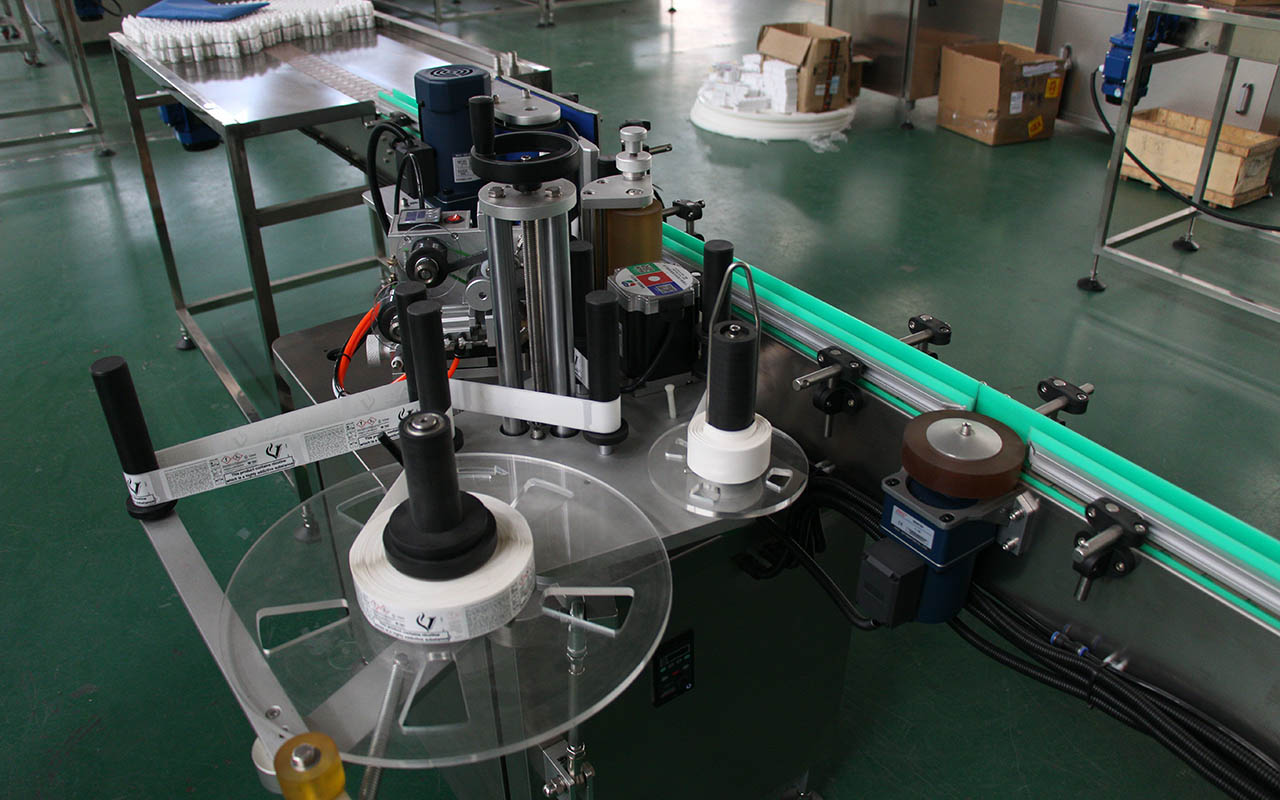

Labeling machine is another important equipment in propolis filling line, its main advantages include:

Automatic labeling: The labeling machine is able to automatically and accurately affix the labels to the containers, avoiding the positional deviation and air bubble problems that may occur during manual labeling.

High precision: The labeling machine adopts a high-precision positioning system to ensure the accurate location of the label and the position of the sticker, which makes the product appearance more beautiful.

Quick change: the labeling machine can be quickly changed according to different products and label sizes, which is convenient for the production of different products on the production line.

To sum up, the automated production process of propolis filling line and the advantages of capping machine and labeling machine can improve the production efficiency, reduce labor cost, and ensure the stability and consistency of product quality and appearance.

Related