Olive Oil Filling Machine

Bottlinglife designs by combining the 3 essential stages to the packaging of your products; filling, capping and labelling.

Tuned by a linear conveyor (or curved depending on your workshop), also fully enclosed, supports a wide variety of caps. Indeed, its capping system operated byelectric screwdrivers is ideal for gun caps, spray caps, dropper caps, and many other types of caps.

Complementary solutions can be added to complete lines (such as rotary accumulation tables, industrial ink jets or thermal transfer encoders) to give you a solution that is completely adapted to your needs.

This Automatic filling machine is specially made for all high and low viscosity materials, such as peanut butter,tomato sauce, soy sauce, medical alcohol, honey, juice ,oil, milk, etc. The machine adopts volumetric piston pump for filling materials. Controlled by servo motor . adjusting the filling weight by touch screen, it can fill from 10ml-1000ml with quick speed and high precision.

Discover all our complete lines on our Youtube channel.

- Speed up to of 40-60bpm

- Independent programmable servo-drive motor for each piston

- Programmable servo-driven bottom-up fill nozzle bar

- Fully tempered glass safety guarding system

- Touch screen control

- Automatic Clean out model

- Fill up to 5L

Filling accuracy expectation of

± 2% (for 0.5 ml to 5 ml fill volume)

± 1% (for 5ml to 15 ml fill volume)

± 0.5% (over 15 ml fill volume)

Filling Nozzle

• Stainless steel 316L

• Spring loaded ball check valve

• With re-enforce silicon hoses (food Grade) for product transfer

• Custom attachment system for BottlingLife equipment

• Final design adapted to the product to be fill (To Be Confirm)

Filling Nozzle with Shut Off System

Preventing dripping with viscous & semi viscous products

• Stainless steel 316L

• Pneumatic activated plunger for sealing the nozzle

• Quick disconnect air hose system for wash down

• Dismantling of the nozzle with the usage of any tools

• With re-enforce silicon hoses (food Grade) for product transfer

Volumetric Piston for Viscous Products

• Ball check valve in stainless steel 316L

• Stainless steel 316L Volumetric chamber

• Pistons with autoclavable packing, FDA approved material

• “Tri Clamp” Attachment system

• Infeed Ø out feed Ø

• Dismantling of the complete piston without tool

• Servo motor control

• Adjustable support legs for in-line positioning and levelling. with ± 38 mm (1 ½ ‘’) adjustment capability

• Raised working surface for easy cleaning

• Machine as multiple brushless motors for a smooth and flexible machine operation

• Electrical and mechanical part located inside the machine frame for a complete protection

• Top plate of the base completely sealed against liquid infiltration protecting all internal mechanical parts

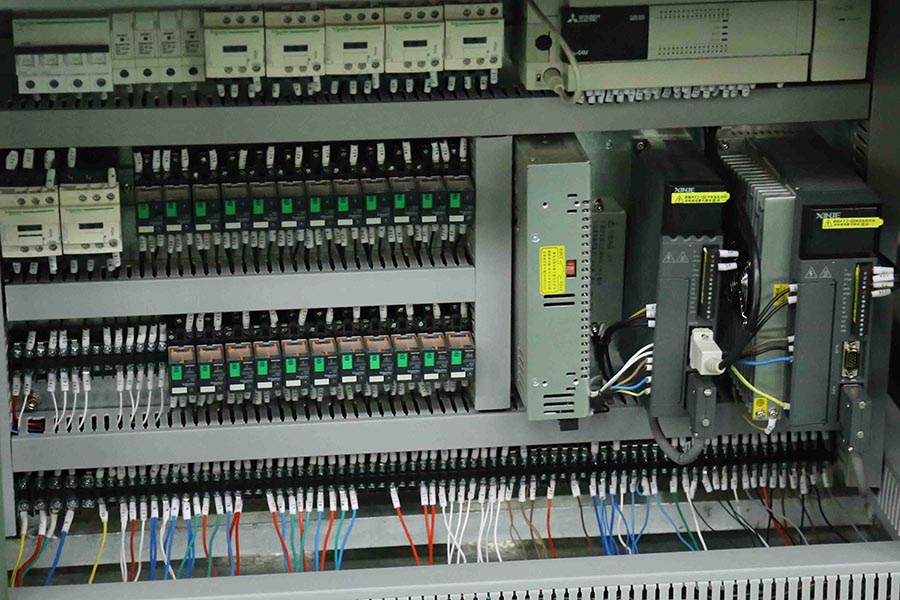

Control System

• Stainless steel panel control

• Stainless steel, tubular holding post with Twin axis swivel panel control

• Emergency Stop on the control panel

• Machine controlled with industrial PLC

• (7’’) multi-color touch screen control• HMI resolution

• Programmable feeder, conveyor speed, etc.

• For normal machine operation with alarm display

• Possibility to have different language interfaces

1.Where is it located the manufacturer?

We are located in shanghai china

2.How long is the warranty?

The warranty is one year with easy damage part for free

3.How long it would take to deliver if I decided to purchase?

Because all of our machine will be customized according to your bottles .so the production time is about 30-40 days after get your bottle samples and deposit .?

4.How is the cost of power per day of the machine?

the machine power need about2kw-5kw

5.In case of breakdown the parts are it easily findable and deliver quickly?

Yes.we will provide you one years warranty with any easy damage spare part for free with free shipping .

6.What resources does your company offer in terms of set up and additional support?

Our engineer is avaliable to set up machine and provide technical support for you.beside this .we provide manual book and video support

7.Can i send bottle and cap test ?how much would you need ?can you make a video of this ?

our machine is customized according to the bottle size and cap size .

when machine is ready we will send you test video with your bottle and caps .bottle we need about 100 for each size .cap we need 200 for each size

8.WHAT ABOUT SPARE PARTS?

We will send enough perishable spare parts for one year with the machine shipped together. We will offer spare parts within the warranty term.

9.HOW DO I TEST THE MACHINE BEFORE SHIPMENT?

We will run the machine for 48 hours .and send you the test video .we can also have remote FAT

10.Do you have certificates?

Yes.we have been certified .we can also provide IQ OQ documentation.