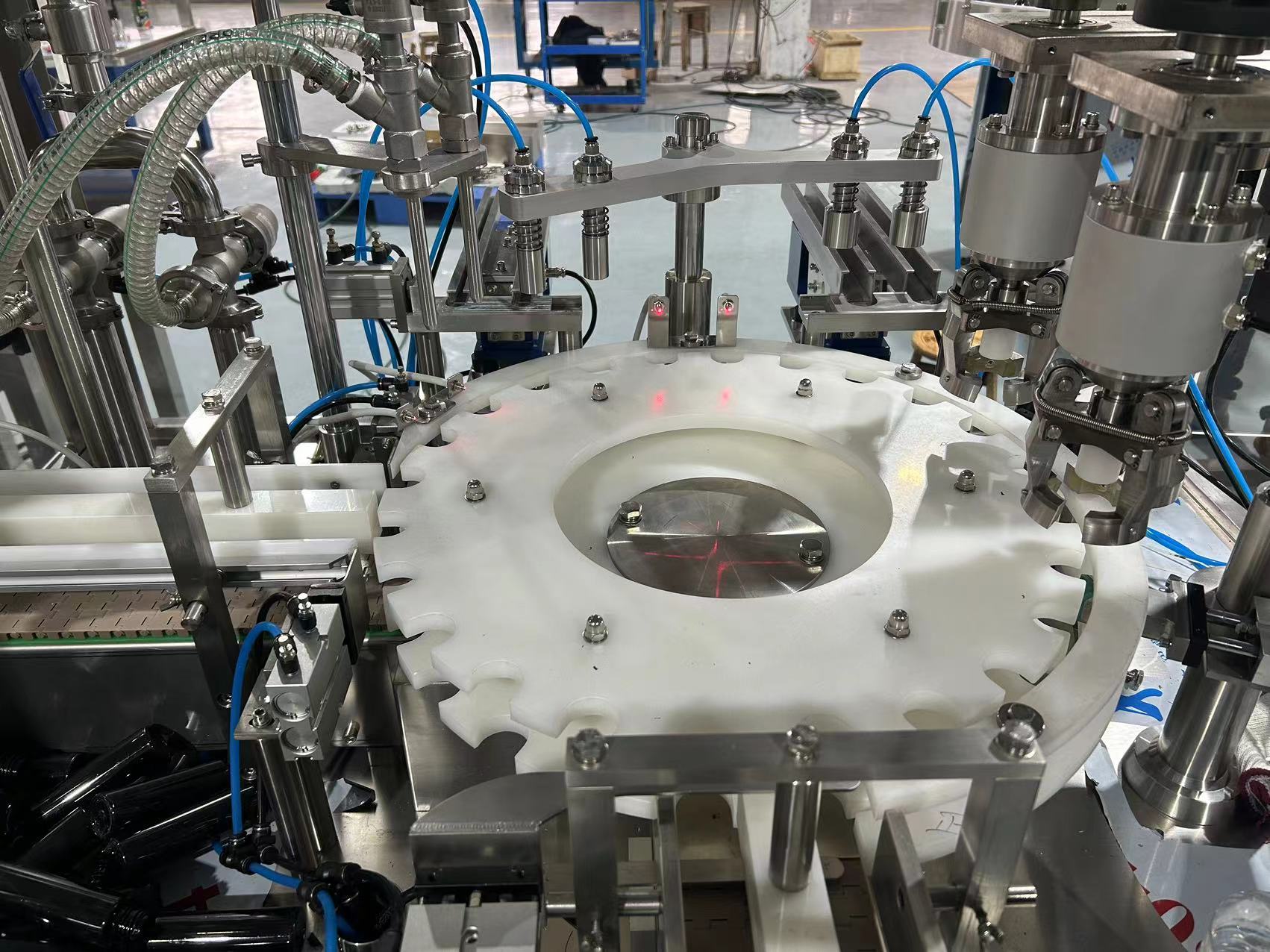

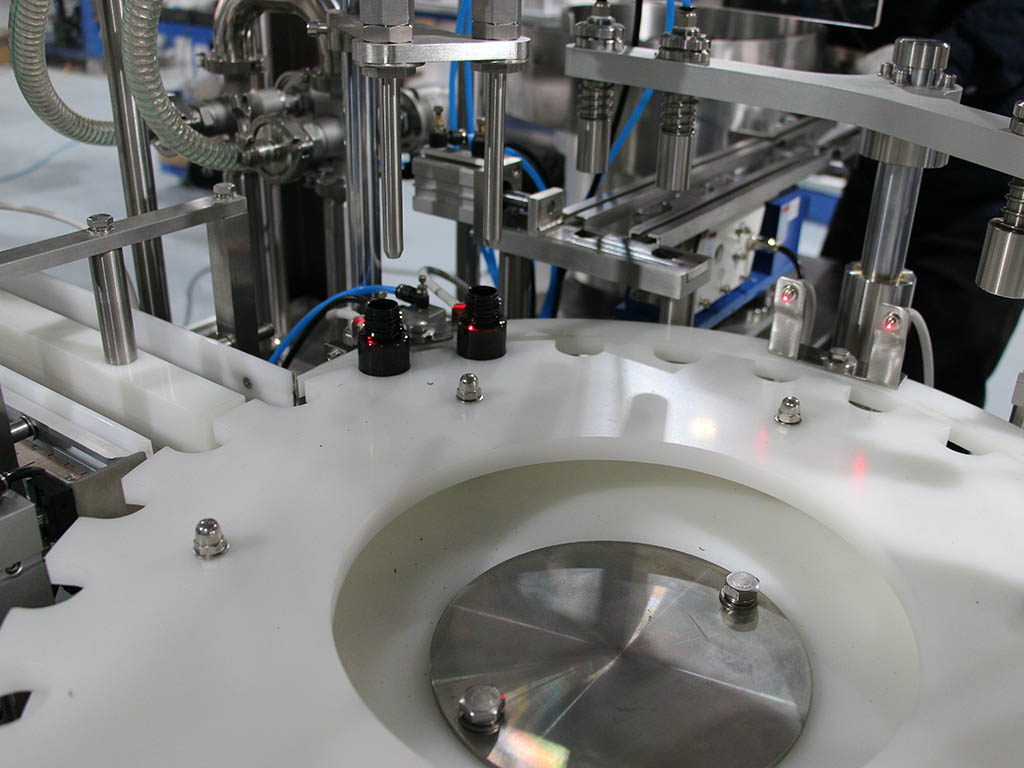

Automatic Chubby Gorrila Bottle Filling Capping Monoblocks

Automatic filling, screwing and labelling monoblocks

This monoblock is suitable for many sectors of activity;

- food industry (flavorings, food dyes…),

- e-liquid (Chubby bottles…),

- parapharmacy (reagents…),

- CBD,

- cosmetics,

- essential oils…

E-liquid fully automatic filling machine is a device specifically designed for filling electronic cigarette liquids. It has the following applications and advantages:

1. Wide application range: suitable for liquid filling of various electronic cigarette products, including e-liquid, syrup, etc.

2. High speed filling: The electronic cigarette fully automatic filling machine adopts advanced filling technology, which can achieve high-speed filling and greatly improve production efficiency.

3. High filling accuracy: This equipment adopts a precise filling system and control technology, which can accurately control the filling amount of each drop of liquid, ensuring stable product quality.

4. Easy to operate: The device adopts fully automated operation, just set the relevant parameters and press the start button to automatically complete the filling process without manual intervention.

5. Display screen operation: The device is equipped with an intuitive and clear display screen, with a user-friendly interface. Operators can directly set and monitor parameters through the touch screen, greatly facilitating operation.

In short, the fully automatic filling machine for electronic cigarettes has the characteristics of high speed, accuracy, and simplicity, which can effectively improve production efficiency and product quality. It is an essential key equipment in the production process of the electronic cigarette industry.

For a comprehensive understanding of our essential oil filling machine and the diverse range of semi-automatic and automatic machines we offer, we invite you to explore our YouTube channel.

- Can fill up to 120 ml

- Meets GMP requirements and follows cGMP guidelines

- rotary filling design

- High-accuracy multi-head filling station

- Diving nozzles for optimized filling cycle

- Positive pick and place plugging station

- Positive pick and place cap placement and/or pre-tightening station

- Independent final cap torquing/crimping station with torque control

Filling Nozzle

• Stainless steel 316L

• Spring loaded ball check valve

• With re-enforce silicon hoses (food Grade) for product transfer

• Custom attachment system for BottlingLife equipment

• Final design adapted to the product to be fill (To Be Confirm)

Filling Nozzle with Shut Off System

Preventing dripping with viscous & semi viscous products

• Stainless steel 316L

• Pneumatic activated plunger for sealing the nozzle

• Quick disconnect air hose system for wash down

• Dismantling of the nozzle with the usage of any tools

• With re-enforce silicon hoses (food Grade) for product transfer

Volumetric Piston for Liquid Products

• Ball check valve in stainless steel 316L

• Stainless steel 316L Volumetric chamber

• Pistons with autoclavable packing, FDA approved material

• “Tri Clamp” Attachment system

• Infeed Ø out feed Ø

• Dismantling of the complete piston without tool

• Servo motor control

Filling accuracy expectation of:

± 2% (for 0.5 ml to 5 ml fill volume)

± 1% (for 5ml to 15 ml fill volume)

± 0.5% (over 15 ml fill volume)

| Description | Automatic Chubby Gorrila Bottle Filling Capping Monoblocks |

| Filling nozzles | customize |

| Filling speed | customize |

| Eligibility rate of inside tuck and outside tuck | ≥99% |

| Air pressure | 0.6Mpa |

1.Where is it located the manufacturer?

We are located in shanghai china

2.How long is the warranty?

The warranty is one year with easy damage part for free

3.How long it would take to deliver if I decided to purchase?

Because all of our machine will be customized according to your bottles .so the production time is about 30-40 days after get your bottle samples and deposit .?

4.How is the cost of power per day of the machine?

the machine power need about2kw-5kw

5.In case of breakdown the parts are it easily findable and deliver quickly?

Yes.we will provide you one years warranty with any easy damage spare part for free with free shipping .

6.What resources does your company offer in terms of set up and additional support?

Our engineer is avaliable to set up machine and provide technical support for you.beside this .we provide manual book and video support

7.Can i send bottle and cap test ?how much would you need ?can you make a video of this ?

our machine is customized according to the bottle size and cap size .

when machine is ready we will send you test video with your bottle and caps .bottle we need about 100 for each size .cap we need 200 for each size

8.WHAT ABOUT SPARE PARTS?

We will send enough perishable spare parts for one year with the machine shipped together. We will offer spare parts within the warranty term.

9.HOW DO I TEST THE MACHINE BEFORE SHIPMENT?

We will run the machine for 48 hours .and send you the test video .we can also have remote FAT

10.Do you have certificates?

Yes.we have been certified .we can also provide IQ OQ documentation.